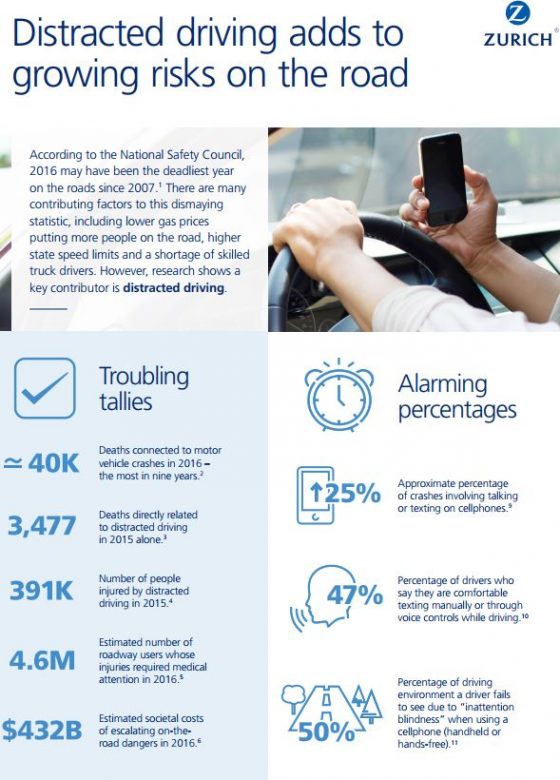

June is Distracted Driving Awareness Month, and while it is quickly drawing to a close, the message remains: Distracted driving is escalating, with 25% more vehicle accidents resulting from drivers talking or texting on cellphones. More cars on the road, especially during summer months, also translates to more accidents.

Organizations with fleets should take note as motor vehicle crashes are the number-one cause of work-related deaths, accounting for 24% of all fatal occupational injuries, according to the National Safety Council (NSC). On-the-job crashes are also costly, with employers sustaining costs of more than ,500 per property damage crash and 0,000 per injury crash.

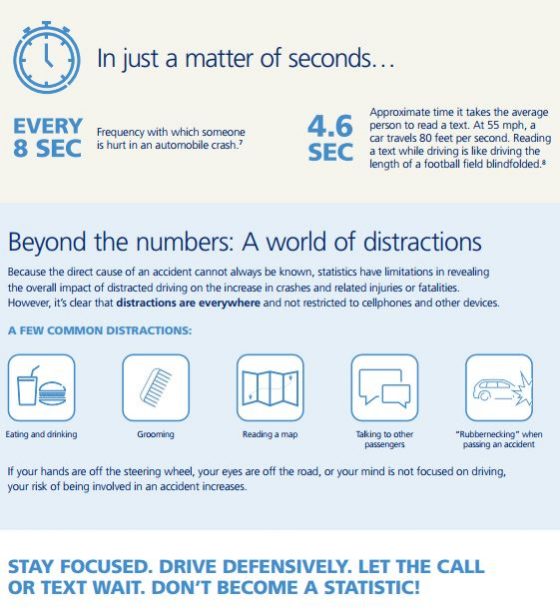

Zurich sums up NSC statistics:

Employers can and are being held liable for damages resulting from employee accidents. “We might expect an employer to be held liable for a crash involving a commercial driver’s license holder who was talking on a cell phone with dispatch about a work-related run at the time of an incident—especially if the employer had processes or a workplace culture that made drivers feel compelled to use cell phones while driving,” the NSC said.

Employers can and are being held liable for damages resulting from employee accidents. “We might expect an employer to be held liable for a crash involving a commercial driver’s license holder who was talking on a cell phone with dispatch about a work-related run at the time of an incident—especially if the employer had processes or a workplace culture that made drivers feel compelled to use cell phones while driving,” the NSC said.

The lines believed to exist between employment-related and personal or private life get blurred in some cases involving:

blurred in some cases involving:

- Cell phones owned by employees as well as employer-provided equipment

- Vehicles that were employee-owned as well as employer-owned or leased

- Situations where employees were driving during non-working hours or were engaged in personal phone calls

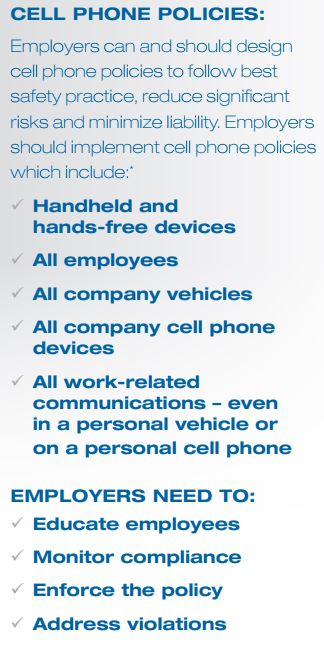

To protect themselves and their employees, the NSC recommended that organizations implement and enforce a total ban policy.

“The best practice is to prohibit all employees from using any cell phone device while driving in any vehicle during work hours or for work-related purposes. Regarding off-the-job hours, precedent has been set by lawsuits.

Thus employers may want to extend their policies to cover off-the-job use of company-provided wireless devices, use of personally-owned devices that are reimbursed by the company, and use of devices in company-provided vehicles. All work-related cell phone use while driving should be banned 24/7,” the NSA advised.

Companies should also pay attention to other common distractions that can lead to accidents, Zurich adds: