An analysis of 11 million workforce drug tests reveals a 10-year high in positive test results, with an increase of 4%, according to the Quest Diagnostics Drug Testing Index (DTI). Post-accident positivity increased 6.

2% in 2015, compared to 2014, and has jumped 30% since 2011.

The report found that amphetamine positivity increased 44% and marijuana positivity increased 26% since 2011; and that nearly half (45%) of individuals in the general U.S. workforce with a positive drug test for any substance in 2015 showed evidence of marijuana use.

Heroin positivity in that period increased 146%. The oxycodone positivity rate has declined annually since 2011, confirming previous research showing that opioid prescriptions have declined in 49 states since 2012, Quest said.

“The DTI statistics for the last five years underscore the threat to employers—and employees—from drug abusers in our workplace. The numbers on hair testing—the methodology with the longest look-back and therefore a more telling measurement of regular use—show a 34% positive-rate increase for illegal drug use by the general workforce in the last five years,” Mark de Bernardo, executive director of the Institute for a Drug-Free Workplace, said in a statement. “However, all the numbers for various testing methodologies confirm this disturbing trend and should provide a wake-up call to employers to do more to combat workplace substance abuse and to do it more effectively.”

Barry Sample, senior director of science and technology at Quest Diagnostics, noted:

- The percentage of employees in the combined U.S. workforce testing positive for drugs has steadily increased over the last three years to a 10-year high of 4.0%.

- According to analysis of urine drug test results, the rate of amphetamine, marijuana, and heroin detection has increased annually for the past five years.

- Positivity rates for post-accident urine drug testing are rising in both the general U.S. and federally-mandated, safety-sensitive workforces; rates have increased 30% and 22%, respectively, since 2011.

- Almost half (45%) of individuals in the general U.S. workforce with a positive drug test for any substance in 2015 showed evidence of marijuana.

- Heroin positivity, indicated by the presence of the 6-AM marker, increased 146 percent between 2011 and 2015 in the general U.S. workforce.

- The overall positivity rate for oral fluid testing increased 47% over the last three years in the general U.S. workforce—equating to almost one in 11 job applicants who are unable to pass an oral fluid drug screen.

- Overall positivity in the general U.S. workforce was highest in hair drug tests, at 10.3% in 2015, a 7% increase over the previous year.

largest meat and poultry processing company, with more than $40 billion in annual sales. The company produces more than 68 million pounds of meat per week. OSHA gave Tyson 15 business days from receipt of its citations to comply, request an informal conference with OSHA’s area director, or contest the citations and penalties before the independent

largest meat and poultry processing company, with more than $40 billion in annual sales. The company produces more than 68 million pounds of meat per week. OSHA gave Tyson 15 business days from receipt of its citations to comply, request an informal conference with OSHA’s area director, or contest the citations and penalties before the independent

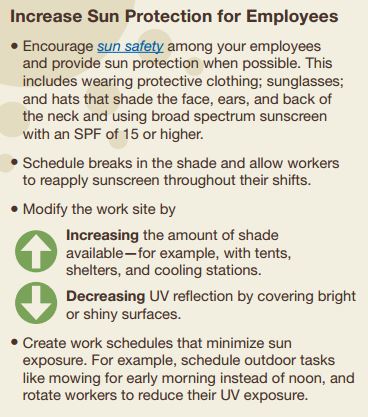

damage connective tissue and increase the risk for developing skin cancer; UVB, which doesn’t penetrate as deeply into the skin, but can still cause some types of skin cancer; and natural UVC, which is absorbed by the atmosphere and does not pose a risk.

damage connective tissue and increase the risk for developing skin cancer; UVB, which doesn’t penetrate as deeply into the skin, but can still cause some types of skin cancer; and natural UVC, which is absorbed by the atmosphere and does not pose a risk.