This week, I ventured up to West Glocester, Rhode Island, home of the coolest place any insurance broker, insurance client, or risk management journalist can visit: the FM Global Research Campus.

Because FM Global is intently focused on prevention of loss as the chief means of minimizing claims, the company maintains a 1,600-acre campus dedicated to property loss prevention scientific research. The biggest center of its kind, the research center features some of the most advanced technology to conduct research on fire, natural hazards, electrical hazards, and hydraulics. Here, experts can recreate clients’ warehouse conditions to test whether existing suppression practices would be sufficient in the event of a massive fire, for example.

buy symbicort online https://royalcitydrugs.com/symbicort.html no prescription

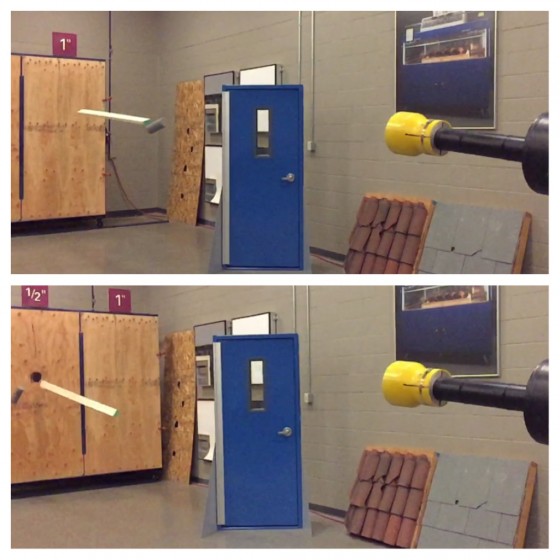

Fabricated hail or seven-foot 2x4s are shot from a cannon-like instrument at plywood, windows, or roofing to test whether these materials can withstand debris that goes flying in hurricane-strength winds. Hydraulic, mechanical and environmental tests are conducted on components of fire protection systems, like sprinklers, to ensure effectiveness overall and under the specific conditions clients face. Further, in cases where there were not sufficient loss prevention solutions, the company’s scientists and engineers have even designed and patented new, more effective sprinklers and other loss prevention technology, the rights to which are released so anyone can manufacture these improved safety measures.

Fire is the leading cause of loss in every calendar year, and watching a pile of plastic pallets ignite into a 60-foot fire while you feel the radiant heat through the glass of the lab’s observation deck is a powerful reality check for anyone evaluating risk exposure in their facility. As you watch the pallets melt, forming a plastic pool that also catches fire and spreads, you see the fire double in size every 45 seconds. If your strategy is primarily to rely on the local fire station, the researchers note, a minimal response time, assuming decent proximity, no traffic or inclement weather, and full staffing, would probably be at least five to 10 minutes. It only took seven minutes for their sample fire to reach almost three stories high, flickering around the edges of the massive ceiling-mounted calorimeter (which measures heat and the particles and smoke released).

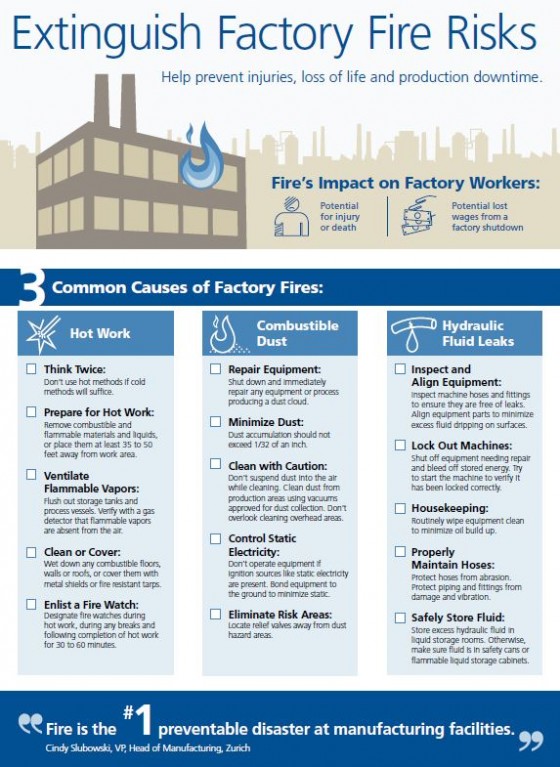

One of the most striking demonstrations comes in the form of a dust explosion. Whether released through product manufacturing, a byproduct of processing, or simply lazy housekeeping, a wide variety of dusts can fill the air in many facilities. Flour, sugar, metal dust, wood and resin are all highly flammable and exceptionally common.

To cause an explosion, you simply need a few conditions: fuel (the dust), oxygen, ignition, suspension (in other words, the dust has not settled, increasing the surface area), and a confined space (ie. inside the facility, the dust stays in the environment). What happens then? Check out the video below for a slow-motion look at the explosion that results from just a hard hat full of phenolic resin.