Ransomware may have waned at the end of last year, but that gave way to straight-up extortion, according to Proofpoint’s newest Quarterly Threat Report, Q4 2018.

Despite a slight resurgence in the middle of last year, ransomware strains appeared in “relatively small, sporadic email campaigns” that by Dec.

31, 2018, comprised one-tenth of 1% of overall malicious message volume.

buy elavil online https://royalcitydrugs.com/elavil.html no prescription

The consequence of this seemingly-good news was that direct extortion once again came en vogue, albeit in cyber form. The newest threats often took the form of “sextortion,” in which actors threaten to reveal compromising information (like revealing photos or video) or take destructive action if the victim does not pay a fee.

Proofpoint theorized that actors have reverted to extortion simply because it is more cost efficient.

The report recommended tips to spot a sextortionist and call their bluff:

With rare exceptions, these emails do not contain malware or malicious links and rely on the human factor to trick recipients. Often, the threatening emails include “evidence” of compromise, such as an old password that the actor may have obtained from a data breach or simply guessed.

Additional findings and highlights from the report included:

- 60% of companies’ domains were spoofed by email fraudsters, a nearly 10% increase from Q3.

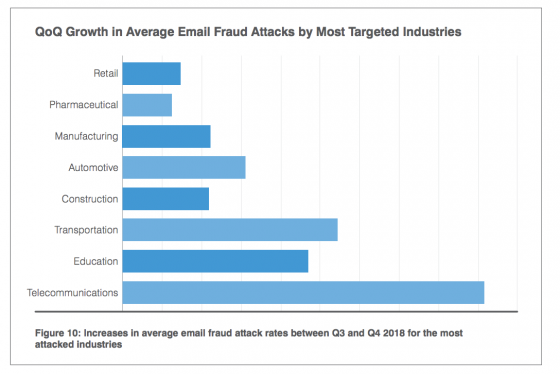

- Email fraud attacks against targeted companies increased by 226% quarter-over-quarter, and 476% vs. Q4 2017. Telecommunications, education and transportation were the industries experiencing this activity most.

- Incidents of social media support fraud, or “angler phishing” – a type of phishing in which attackers attempt to insert themselves in legitimate conversations between consumers and brand-owned social media accounts – increased by nearly 40% from the prior quarter and saw an overall increase of 500% in 2018.

- Emails leveraging malicious URLs outnumbered malicious attachments by roughly two-to-one for Q4 and three-to-one for the entire year.

Visit here for Proofpoint’s full quarterly report.