The Transportation Security Administration (TSA) had a presence in New York’s Penn Station this week, as it partnered with Amtrak to test new security technology that can help prevent and detect risks of terrorism and violence.

The TSA set up a passive system known as a stand-off explosive detection unit at the Amtrak concourse to identify individuals carrying/wearing a person-borne improvised explosive device (PBIED), such as a suicide bomb or vest. Such a vest was worn by terror suspect Akayed Ullah, when he attempted to blow himself up in a tunnel connected to the Port Authority in Midtown Manhattan last December.

The TSA set up a passive system known as a stand-off explosive detection unit at the Amtrak concourse to identify individuals carrying/wearing a person-borne improvised explosive device (PBIED), such as a suicide bomb or vest. Such a vest was worn by terror suspect Akayed Ullah, when he attempted to blow himself up in a tunnel connected to the Port Authority in Midtown Manhattan last December.

The system will be tested at Penn Station through the end of this week and operated by Amtrak police officers. TSA spokesperson Lisa Farbstein said that local enforcement agents can be trained on the technology and laptop in one day and that local police would establish protocol if a weapon were to be detected.

According to TSA information, the unit’s main feature is a screening technology that can be used by Amtrak and mass transit agencies to detect potential threats—metallic or non-metallic—by identifying objects that block the naturally-occurring emissions emitted by a person’s body.

The unit does not emit any radiation and no anatomical details of a person are displayed.

The use of the detection technology enables a rail or transit agency to help safeguard against terrorist threats in a mass transit environment.

The TSA is supplying two models of the equipment for the purposes of the demonstration. One model is mounted on a tripod, the other is contained in a trunk.

The equipment is mobile, which allows agencies to easily relocate it to different stations. Users operate it via a laptop computer in the station. The image that appears on the laptop reveals concealed objects that block the body emissions and indicate the location and size of those objects on a green image of an individual.

Penn Station was the most recent stop in the new technology’s national testing tour. In December 2017, the scanners were used in the Los Angeles 7th Street metro station where more than 86,000 people pass through each weekday; one month earlier they were used by Amtrak in Washington, D.C. They were also used in Secaucus, New Jersey in 2014 as riders made their way to MetLife Stadium for Super Bowl XLVIII.

Earlier this month, Amtrak President Richard Anderson told the

Earlier this month, Amtrak President Richard Anderson told the  DWR Photo: Lake Oroville on Jan. 19, 2018 with lake levels at 707 feet.

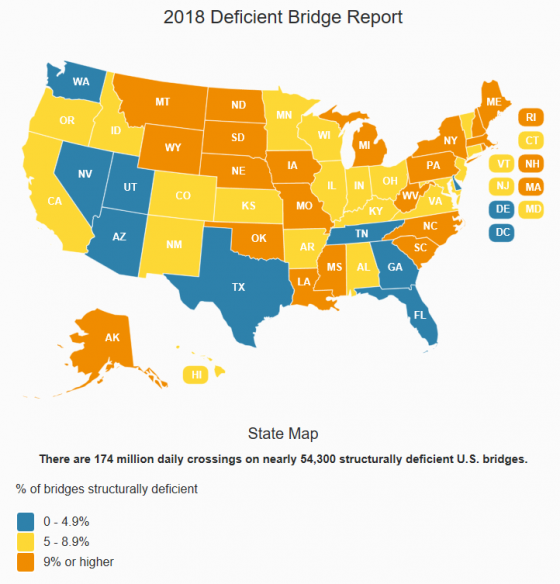

DWR Photo: Lake Oroville on Jan. 19, 2018 with lake levels at 707 feet. More than 54,000 bridges along the Interstate Highway System in the United States

More than 54,000 bridges along the Interstate Highway System in the United States